Capabilities

Deep-Dive into a comprehensive list of our capabilities

What We Offer

Mincham’s priority is to service, develop and produce advanced light-weight solutions for the defence, aerospace and high-tech’ industries.

We have broad capabilities and focus on producing flexible solutions for our customer; by specialising in the design, prototyping, production and through-life support of advanced light-weight structures to globally recognised standards.

Composites

Composite Ovens Small – Large

Vac Units

Temp Units

Hot Bonder

160 Tonne Press

Autoclave Small: (1.5m x 1.5m)

- Autoclave Large: (3m x 8m)

CNC Lathe

CNC Milling Machine

CNC Router

CNC Stenciling

Downdraft Spray Booth

Model: EC 3m X 8m

The Econoclave is an energy efficient composites bonding autoclave designed for medium to large sized production parts.

It provides:

- Useable Diameter of 3000mm (118″) and a working length of 8000mm (314″).

- Maximum operating temperatures of 250C and a maximum operating pressure of 10 bar.

- Aerospace-grade autoclave, designed for composite bonding and curing

- CPC (Composite Processing Control) system, the most popular controls package in the world for composite curing.

Model: Vacuum-Press International INC 1.5m x 1.5m

This autoclave is ldeal for small sized production parts.

It provides:

- Useable diameter of 1500mm (60″) and a working length of 1500mm (60″)

- Maximum operating temperatures of 250c and maximum operationg pressures of 10 bar

- Aerospace-grade autoclave, designed for composite bonding and curing

- Indigenous Composite Processing Control system

Carbon Fibre

Kevlar (Aramid)

E, S and Quartz Glass

Honeycomb

Prepreg

Autoclave

Wet Lay-up

Vacuum Bagging

Pressure Moulding

Resin Transfer

Oven Cure

Resin Infusion

CNC 3D Profiling

Machining and Sheet Metal

Welding Ovens

- Guillotines – 3m

- Welders: TIG, ARC, OXY & MIG

- Saws – Horizontal and Vetical

- Press 160 Tonne (4 Post)

- 3.0m and 1.5m Pres Brake NC

- Blasting

- Sheet Rollers – 1.2m and 2.4m

Sheet Notcher

- CNC Lathe

- CNC Milling Machine 1.5m x 0.75m x 0.7m

- CNC Router 2.5m x 1.5m

- CNC Stenciling

- Downdraft Spray Booth

- Coordinate Measuring Machine 900cm

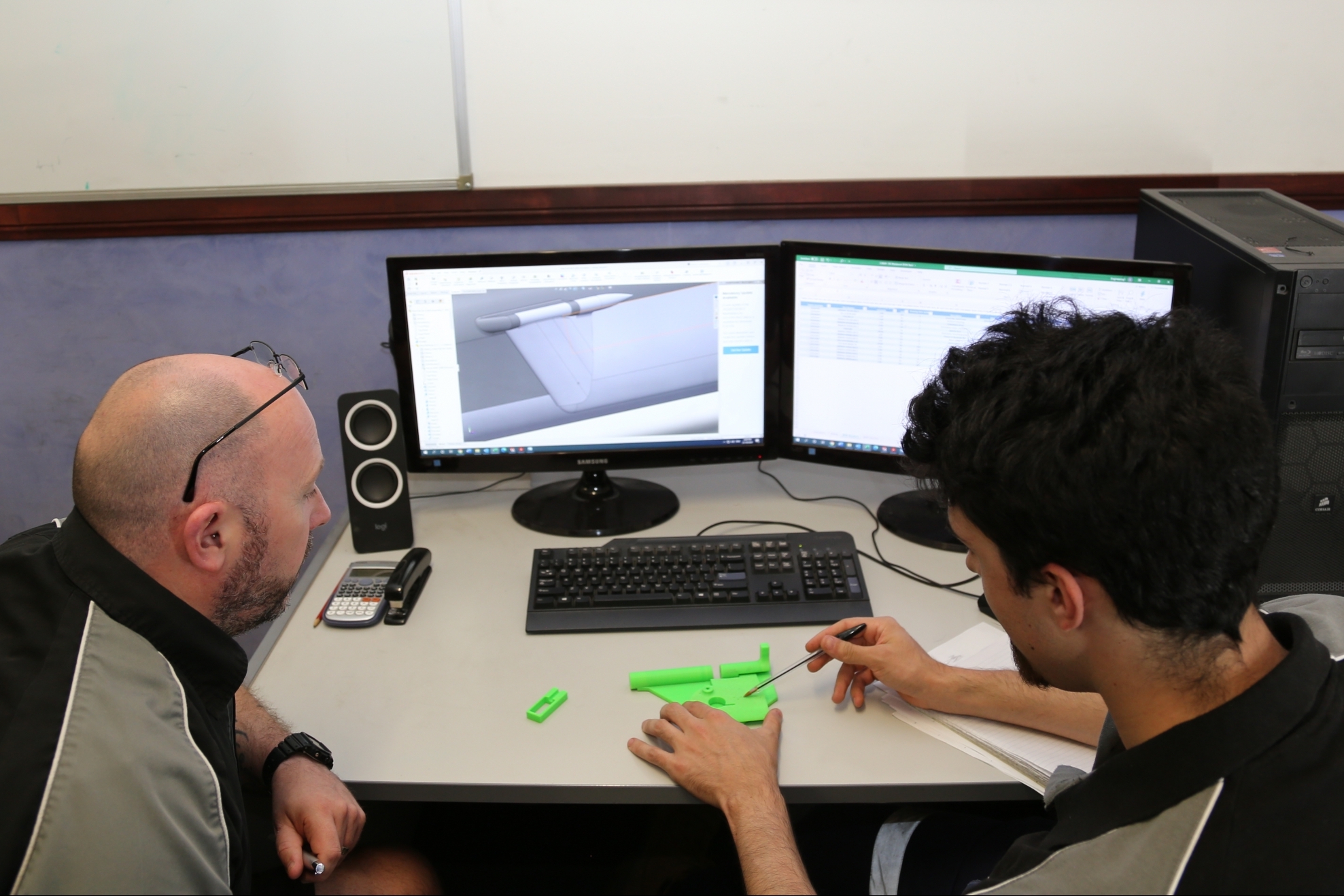

Engineering Design Services

- Design Engineering

– Catia v5, Solidworks and simulation tools - Material Development & Testing

- Process Engineering and Automation

- Tooling design

- Program managment

- Access to University laboratories

- Ballistics

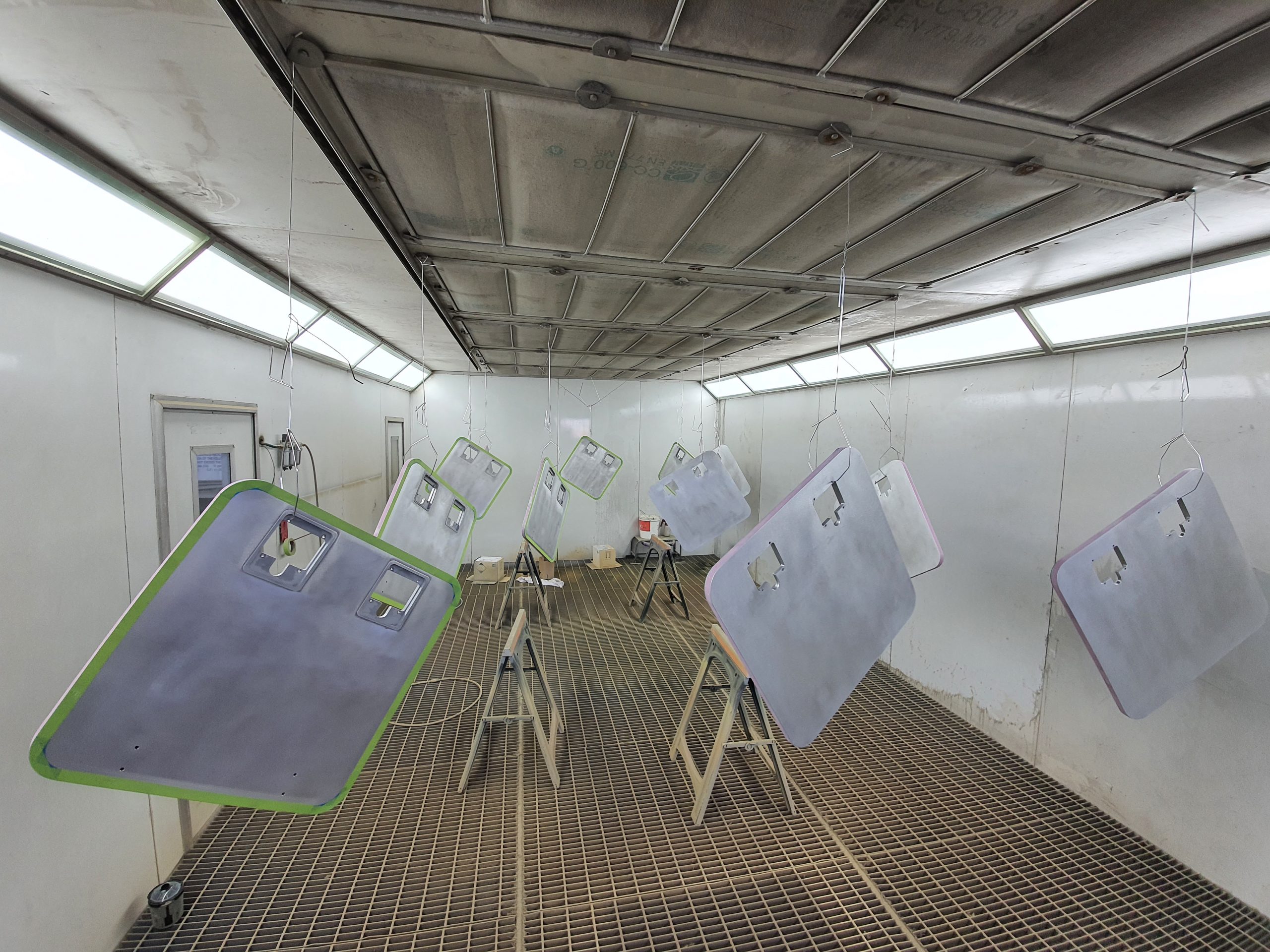

Painting and Finishing Services

Mincham has been performing component finishing for over 20 years, a recent investment into our painting capability sees us upgrade to a larger down-draft spray booth with bake capability. Further to this we now have 4 full size priming/preparation down draft booths.

Products

Autonomous Systems

Aeromedical

Aerial Delivery Systems

Suppressor Systems

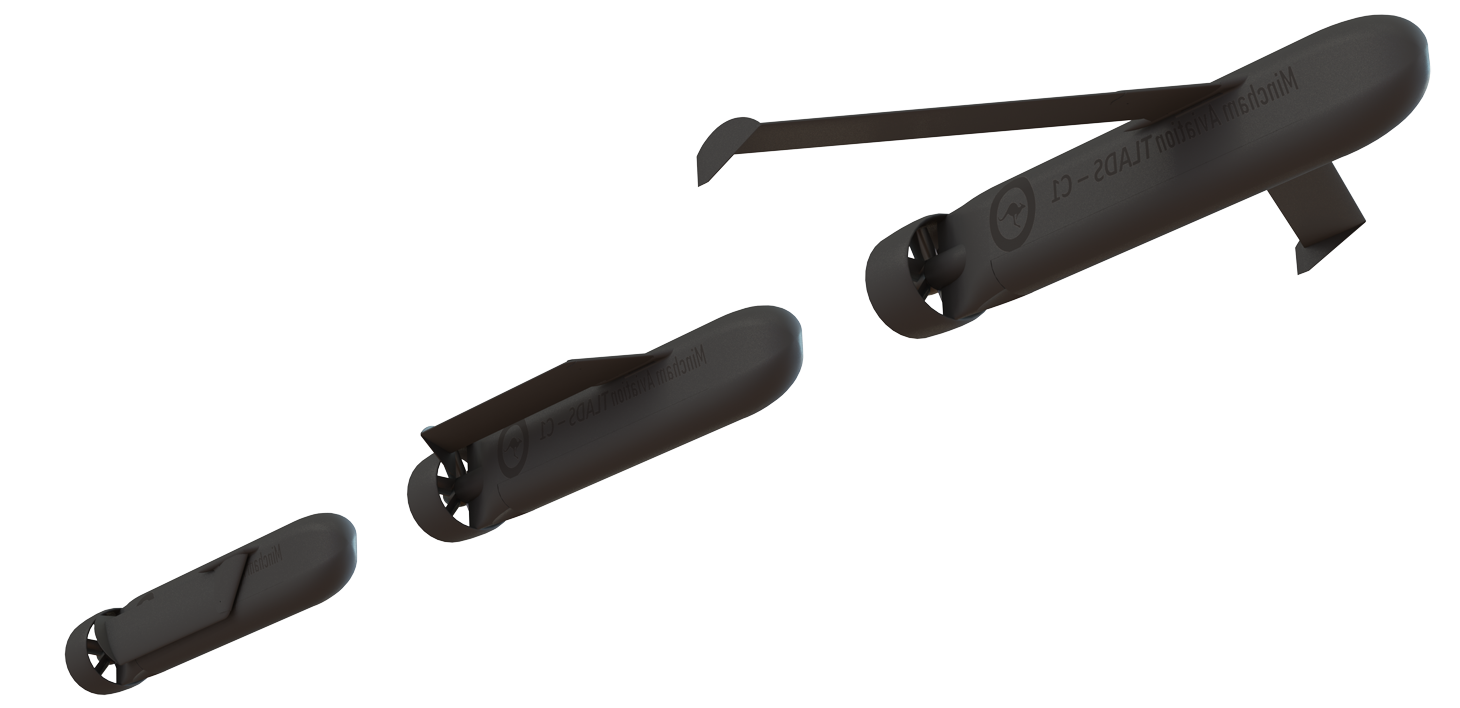

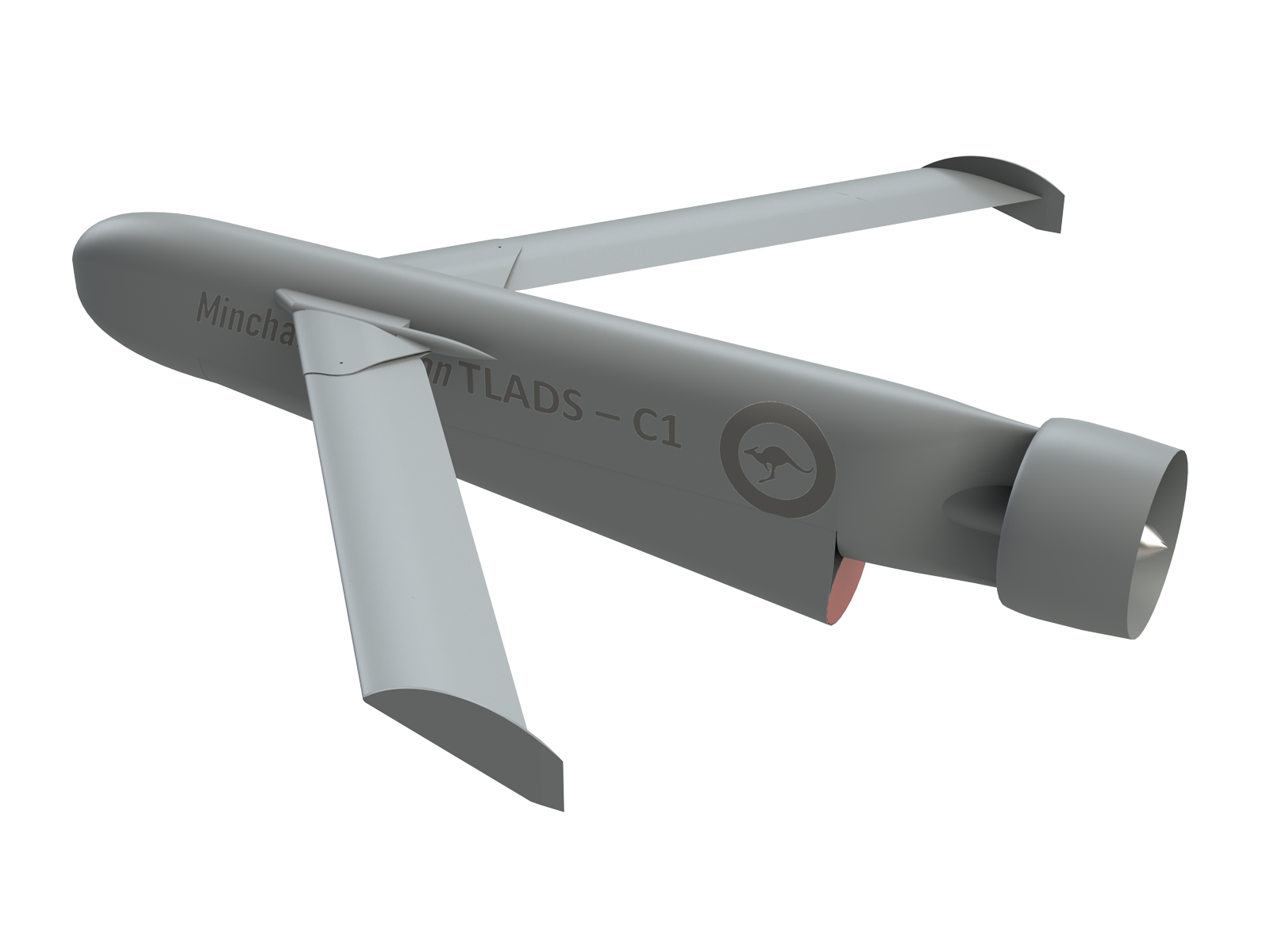

Advanced Autonomous Systems

Tube Launched Aerial Delivery System (TLADS) Payloads:

- Sonobuoys (A-class)

- Torpedo Decoys

- Training Aids

- Life Raft Systems

- Magnetic Anomaly Detector (MADS)

- Electronic Anomaly Sensory (ESM)

- Radio Relay

- An Electromagnetic Pulse Generator (EMP)